CPP Fluids

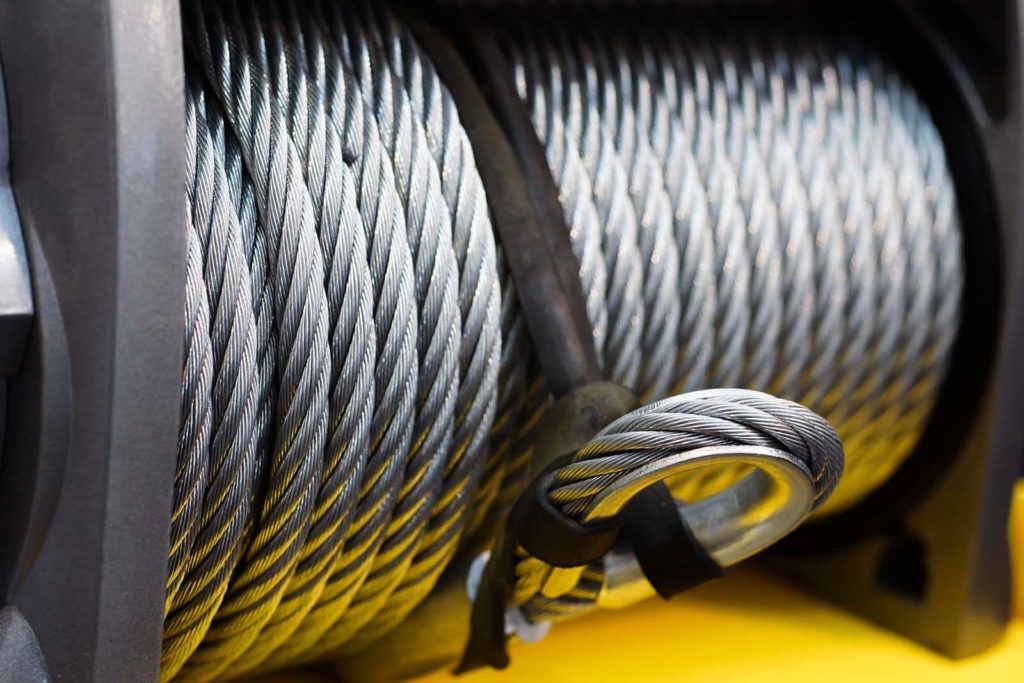

Vickers Oils has a range of VGP compliant products which have been approved by various OEMs for use in controllable pitch propellers (CPPs) where there is potential for fluid loss to the environment to occur.

ECOSURE HSE and BIOGEAR XP provide excellent equipment protection, superior thermal stability, exceptional oxidation resistance and good anti-wear performance under severe conditions.

Our range of environmentally acceptable lubricants (EALs) for this application are based on fully saturated synthetic esters and meet the detailed ecological definitions and requirements laid down in Vessel General Permit (VGP).

Products typically used in this application include ECOSURE HSE 32, ECOSURE HSE 46, ECOSURE HSE 68, ECOSURE HSE 100, BIOGEAR XP 68, HYDROX BIO 100 and HYDROX BIO 150. For further information please use the following link to contact us and provide some further background information to enable us to provide some specific advice.

NEOX DT can be used for the lubrication and protection of the CPP hub unit where mineral grease packing is required and where sea water, fresh water or condensation moisture may occur.

Explore our range of Innovative and OEM Approved Lubricants

Trusted for Generations

An award-winning range of EALs (Environmentally Acceptable Lubricants)

Regional stock points

in over 40 locations

Ability and infrastructure to respond quickly to urgent requirements

Service & Support

30% of our workforce are employed in the technical team, focusing on Quality Control, R&D, OEM liaison and Technical Service allowing us to provide one-on-one dedicated customer support by our team of highly qualified experts.